BASF Ultrafuse® ABS Fusion+

$30.55 $33.95

ABS Fusion+ made with Polyscope XILOYTM 3D is an engineering filament which has been optimized for 3D printing. This special grade has been developed in collaboration with Polyscope Polymers renowned for its material solutions in the automotive industry. ABS is a thermoplastic which is used in many applications.

color

Diameter

Weight

Choose Quantity

Product Details

Specifications

Ultrafuse® ABS Fusion+ is an easy-to-print engineering material and enables a much more efficient printing process. Meaning 3D printing operators will spend less time tinkering and more time exploiting the full potential of your 3D printing rig. To top it off, Ultrafuse® ABS Fusion+ adheres to water-soluble support – no more hassle with chemicals, just dissolve your support in water after printing!

The 3D printing community has so far considered ABS an unforgiving material: Now, thanks to the unique properties of ABS Fusion+ you can look forward to a high success rate with greatly improved dimensional stability.

Benefits:

- Easy to print

- Direct printing on heated glass or print bed surfaces

- High heat resistance

- Adheres to water soluble support

Applications:

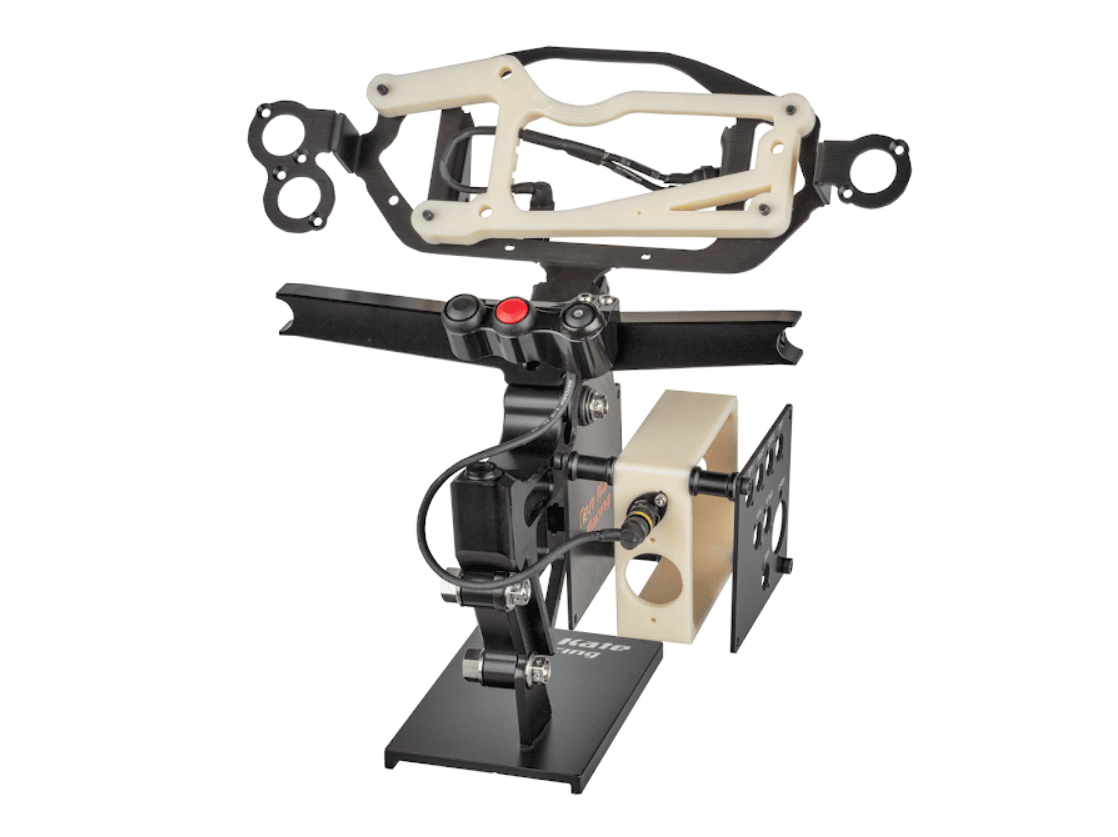

- Jigs and fixtures

- Automotive part

Ultrafuse® ABS Fusion+

- Tensile Strength (MPa):17.9 (ZX), 29.5 (XY)

- Flexural Modulus (MPa):878 (ZX), 1133 (XZ), 1406 (XY)

- Elongation at Break:2.1 % (ZX), 10.9 % (XY)

- Impact Strength Izod notched (kJ/m2):2.2 (ZX), 38.4 (XZ), 26.4 (XY)

- Impact Strength Izod unnotched (kJ/m2):6.6 (ZX), 131.1 (XZ), 73.1 (XY)

- HDT @ 0.45 MPa:91°C

- Bed Temperature:100 - 120 °C

- Bed Material:Glass (use a small amount of adhesive spray to protect the glass bed)

- Nozzle Diameter:≥ 0.4 mm

- Print Speed:40 -80 mm / s