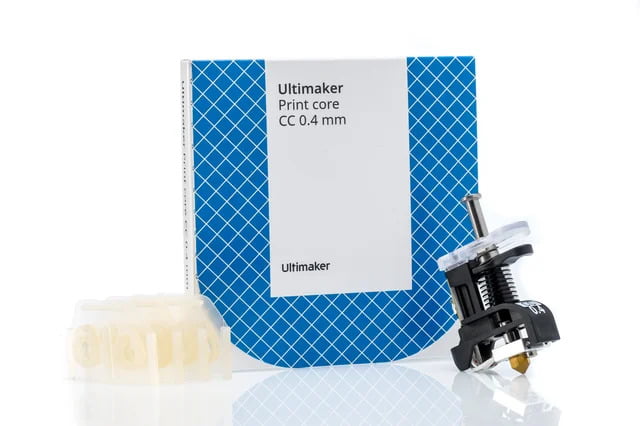

UltiMaker Print Core CC

$299.00

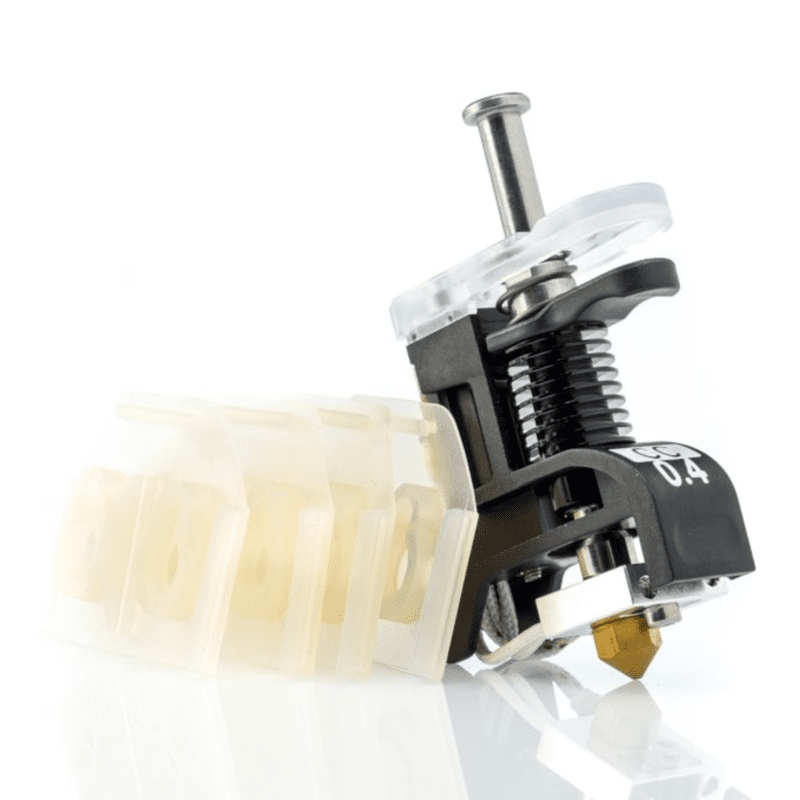

The Ultimaker print core CC 0.4's smaller nozzle size means your prints will feature higher levels of detail, thinner line widths, and a smooth surface finish – enabling you to print parts or prototypes with the visual quality you need.

Product Details

Print core CC

Built for high-strength applications

Built for high-strength applications

Looking for a way to print stronger parts? With a wear-resistant steel nozzle, the print core CC unlocks the power of high-strength applications with extra stiffness and rigidity, using a wide range of composite materials from the Ultimaker ecosystem.

Why is the design of the CC print core updated?

The print core CC design is a new iteration of the print core CC Red. This new design features updated components that are more robust, leading to an increased reliability when using it

The print core CC design is a new iteration of the print core CC Red. This new design features updated components that are more robust, leading to an increased reliability when using it

What is the key value of the print core CC?

The print core CC is built for unlocking high-strength applications with composite materials, by making use of multiple nozzle sizes and composite materials from the Ultimaker ecosystem.

The print core CC is built for unlocking high-strength applications with composite materials, by making use of multiple nozzle sizes and composite materials from the Ultimaker ecosystem.

For what applications are the CC print cores most suitable?

Since the print core CC is designed for working with abrasive composite materials, it is mainly suitable for applications that require high strength, with extra stiffness and rigidity. These types of applications can be functional prototypes, but also manufacturing aids or end-use parts can benefit from these properties.

Since the print core CC is designed for working with abrasive composite materials, it is mainly suitable for applications that require high strength, with extra stiffness and rigidity. These types of applications can be functional prototypes, but also manufacturing aids or end-use parts can benefit from these properties.

What are the differences between the print core CC 0.4 and 0.6?

By offering multiple CC print cores we give customers maximum flexibility for optimizing their composite applications. They mainly differ in terms of the level of visual quality and print time:

By offering multiple CC print cores we give customers maximum flexibility for optimizing their composite applications. They mainly differ in terms of the level of visual quality and print time:

- Print core CC 0.4 The Ultimaker print core CC 0.4's smaller nozzle size means your prints will feature higher levels of detail, thinner line widths, and a smooth surface finish – enabling you to print parts or prototypes with the visual quality you need

- Print core CC 0.6 The Ultimaker print core CC 0.6 prints with bigger line widths, meaning your composite applications will be ready as quickly as possible – saving you time in a busy, hardworking environment that requires efficiency and speed