BAMBU LAB X1E

The Bambu X1E is a state-of-the-art 3D printer tailored for professionals. It offers enhanced connectivity with stable Ethernet and WPA2-Enterprise Wi-Fi options.

Operating off-cloud in LAN Only Mode, it enables remote control through local networks without internet dependency. With heavy-duty air filtration, active heating, a high nozzle temperature of 320°C, and a robust CoreXY structure, the Bambu X1E delivers fast, stable, and high-quality prints. Incorporating AI failure detection and intelligent filament management, it minimizes wastage and downtime, making it a versatile and efficient solution for advanced 3D printing applications.

*Limited Stock — Expected Lead Time: 2-3 Weeks*

$2,499.00

Smart Filament ManagementSmart Filament Management on the X1E includes auto filament reload and facilitates multi-material printing with support material, enhancing surface quality. The X1E can parallelly connect four Bambu AMS systems, accommodating up to 16 filament spools, suitable for seamless surface printing and multi-color applications. The AMS system also automates filament reload, ensuring complete utilization of one spool before transitioning to the next.

Smart Filament Management

Smart Filament Management on the X1E includes auto filament reload and facilitates multi-material printing with support material, enhancing surface quality. The X1E can parallelly connect four Bambu AMS systems, accommodating up to 16 filament spools, suitable for seamless surface printing and multi-color applications. The AMS system also automates filament reload, ensuring complete utilization of one spool before transitioning to the next.

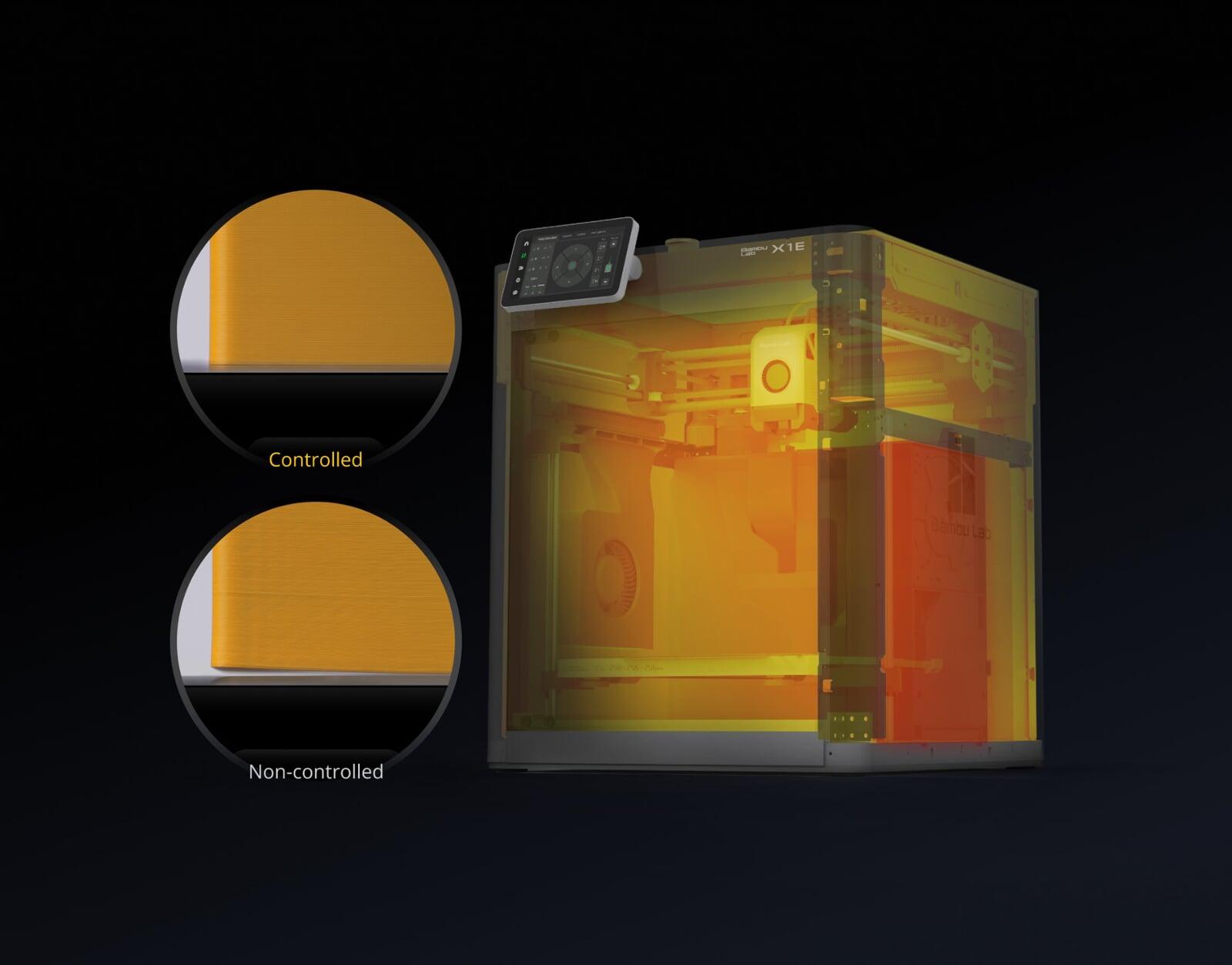

Control Warping and Enhance Layer Bonding

Active Heating and Precise Chamber Temperature Control on the X1E mitigate warping and enhance layer bonding. The printer actively heats and regulates the chamber temperature, ensuring accurate control (up to 60°C or 140°F). This precision is particularly beneficial for filaments susceptible to warping, like ABS and PC, leading to improved overall print quality.

Control Warping and Enhance Layer Bonding

Active Heating and Precise Chamber Temperature Control on the X1E mitigate warping and enhance layer bonding. The printer actively heats and regulates the chamber temperature, ensuring accurate control (up to 60°C or 140°F). This precision is particularly beneficial for filaments susceptible to warping, like ABS and PC, leading to improved overall print quality.

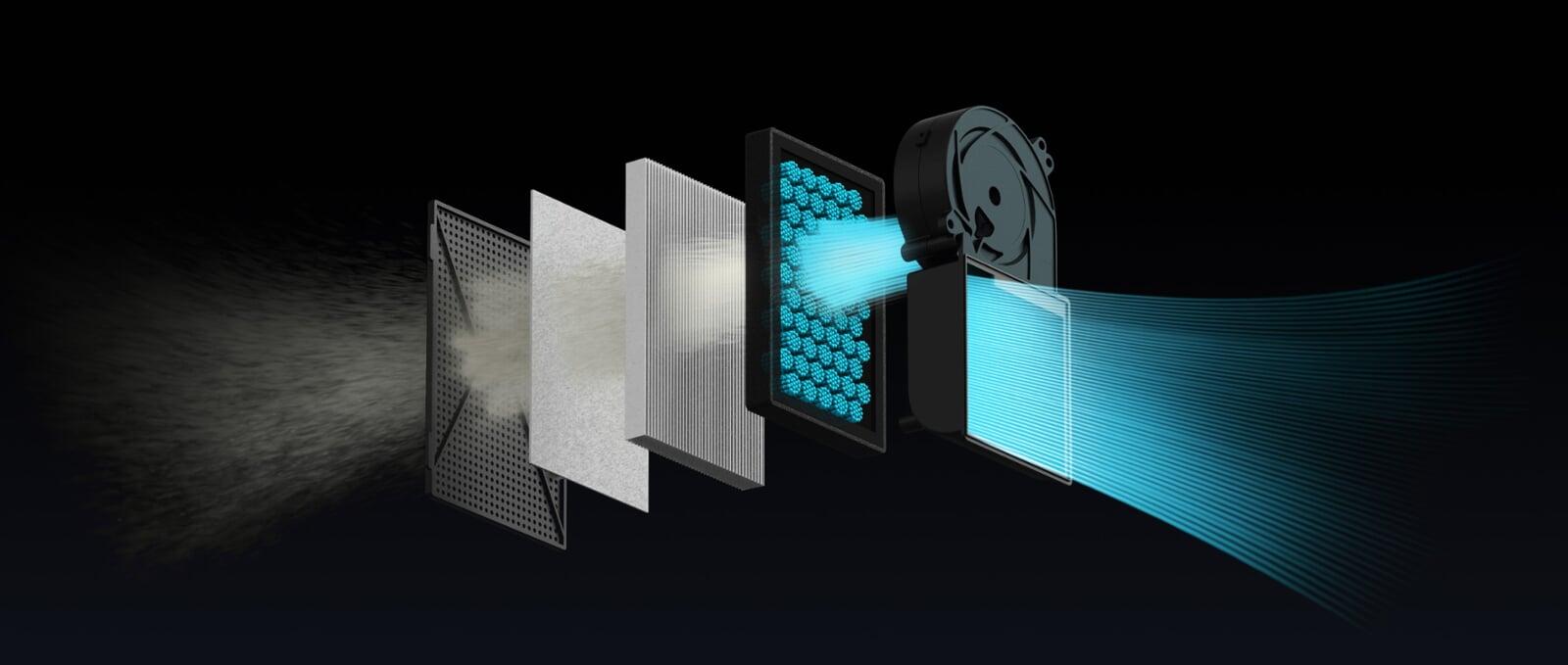

Robust Air Filtration System Effectively Eliminates Particulates and VOCs Produced During 3D Printing. The advanced filtration system combines a G3 pre-filter, an H12 HEPA filter, and a high-quality coconut shell activated carbon filter for optimal air purification. This enhanced filtration capability significantly reduces unwanted odors and particulate matter, particularly beneficial in less ventilated printing environments.

Robust Air Filtration System

Effectively Eliminates Particulates and VOCs Produced During 3D Printing. The advanced filtration system combines a G3 pre-filter, an H12 HEPA filter, and a high-quality coconut shell activated carbon filter for optimal air purification. This enhanced filtration capability significantly reduces unwanted odors and particulate matter, particularly beneficial in less ventilated printing environments.

Nozzle Temperature of 320°C (608 °F)

Enhanced Heat for Advanced Materials. The elevated nozzle temperature allows for the printing of high-performance materials like PPA-CF/GF, PPS, and PPS-CF. These innovative materials exhibit superior dimensional stability, heat resistance, and mechanical performance.

Nozzle Temperature of 320°C (608 °F)

Enhanced Heat for Advanced Materials. The elevated nozzle temperature allows for the printing of high-performance materials like PPA-CF/GF, PPS, and PPS-CF. These innovative materials exhibit superior dimensional stability, heat resistance, and mechanical performance.

Durable High-Speed CoreXY Exceptionally Swift and Sturdy Framework for Continuous High-Speed Printing. The CoreXY motion structure, featuring superior carbon-fiber rods, empowers the X1E to achieve a toolhead acceleration of 20,000 mm/s² by minimizing the weight of moving components. This heightened acceleration enables the X1E to sustain its maximum travel speed of 500 mm/s for extended durations, substantially minimizing the overall print time.

Durable High-Speed CoreXY

Exceptionally Swift and Sturdy Framework for Continuous High-Speed Printing. The CoreXY motion structure, featuring superior carbon-fiber rods, empowers the X1E to achieve a toolhead acceleration of 20,000 mm/s² by minimizing the weight of moving components. This heightened acceleration enables the X1E to sustain its maximum travel speed of 500 mm/s for extended durations, substantially minimizing the overall print time.

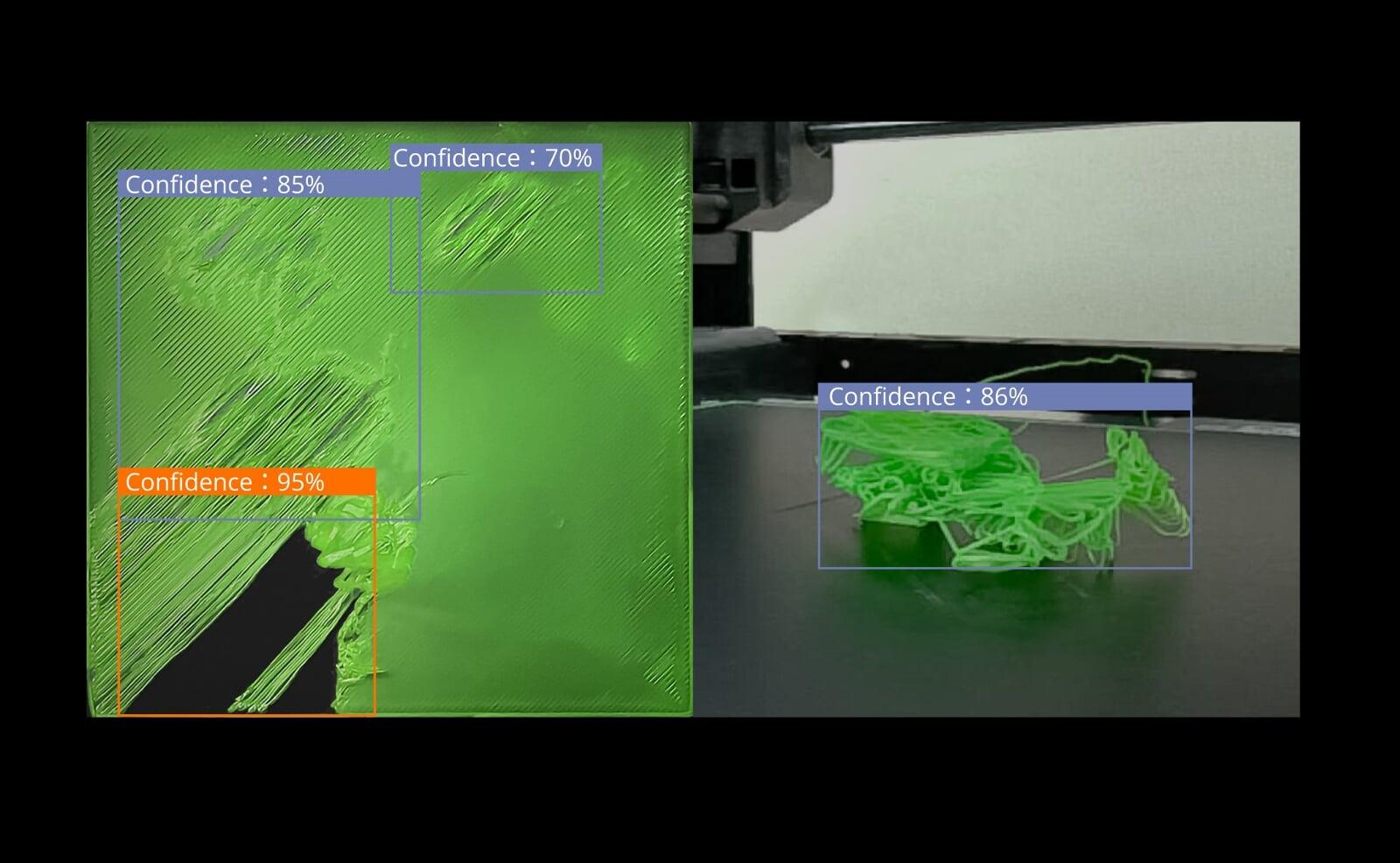

AI-Based Failure Detection Minimize Filament Waste and Machine Downtime Utilizing Lidar and computer vision, the X1E's AI algorithm proficiently identifies first-layer imperfections and spaghetti failures. Subsequently, it autonomously halts the print process, effectively averting catastrophic failures and reducing both filament waste and machine downtime.

AI-Based Failure Detection

Minimize Filament Waste and Machine Downtime Utilizing Lidar and computer vision, the X1E's AI algorithm proficiently identifies first-layer imperfections and spaghetti failures. Subsequently, it autonomously halts the print process, effectively averting catastrophic failures and reducing both filament waste and machine downtime.

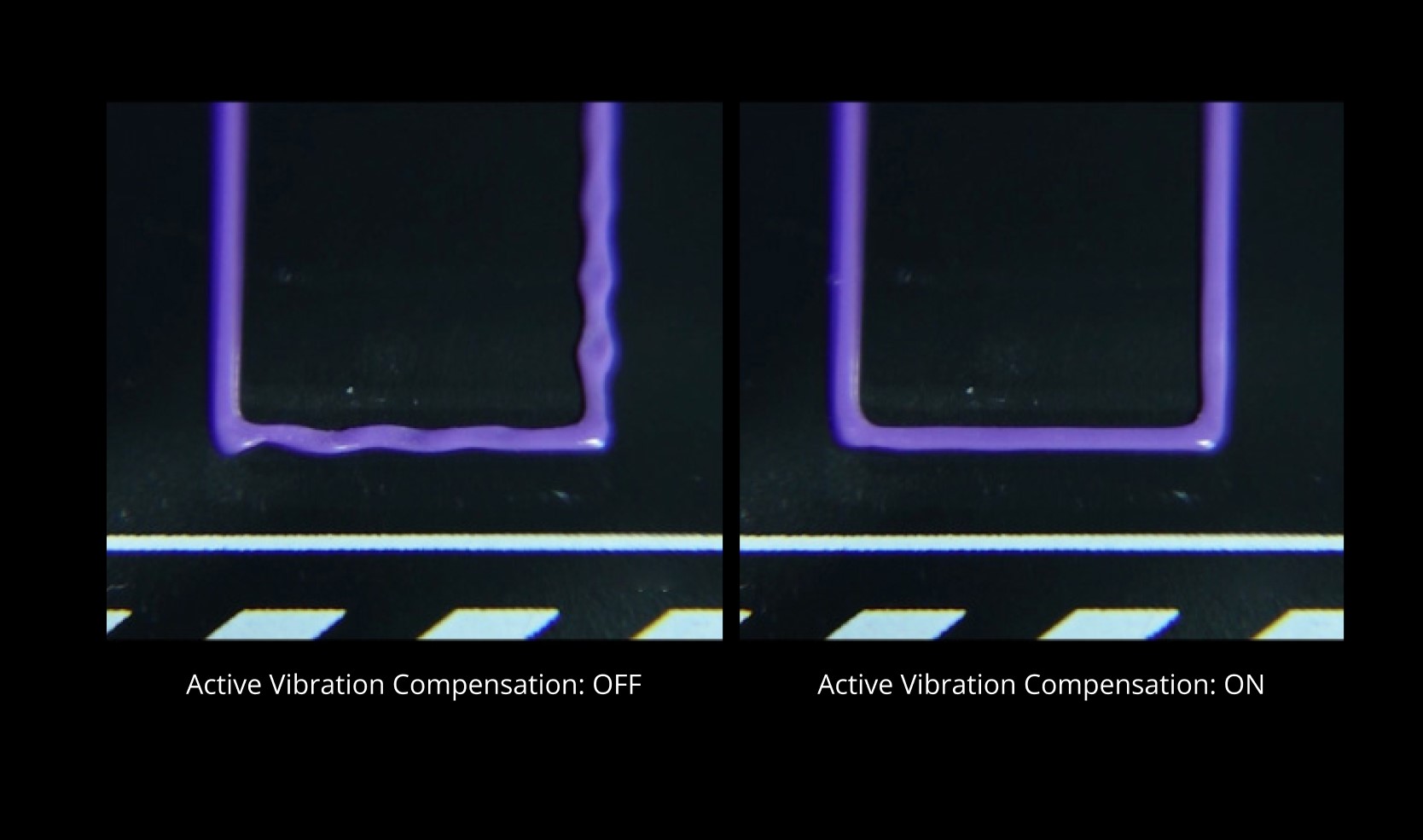

Vibration and Extrusion Adjustment Consistent and High-Quality Prints, Even at Elevated Speeds. The X1E proactively corrects XY-axis vibrations and extrusion concerns, guaranteeing remarkably smooth print quality without the requirement for manual adjustments. All measurements are fully automated, ensuring stability and superior print quality, even at higher speeds.

Vibration and Extrusion Adjustment

Consistent and High-Quality Prints, Even at Elevated Speeds. The X1E proactively corrects XY-axis vibrations and extrusion concerns, guaranteeing remarkably smooth print quality without the requirement for manual adjustments. All measurements are fully automated, ensuring stability and superior print quality, even at higher speeds.

Bambu Lab X1E Specifications

| Wi-Fi Frequency Range: | 2400 MHz - 2483.5 MHz |

| WPA2-Enterprise: | EAP-PEAP EAP-TLS TAP-TTLS |

| Ethernet Ethernet Socket: | RJ45 |

| Ethernet Speed: | 100 Mbps / Full Duplex |

| Active Chamber Heating: | Yes |

| Maximum Chamber Control Temperature: | 60℃ |

| Pre-filter grade: | G3 |

| HEPA filter grade: | H12 |

| Max Hot End Temperature: | 320℃ |

| Build Plate: | Flexible Steel Plate |

| Max Acceleration of Toolhead: | 20000 mm/s2 |

| Bambu Micro Lidar: | Yes |

| Chamber Monitoring Camera: | 1920*1080 Included |

| Net Weight: | 16kg |

| Activated Carbon Filter type: | Coconut Shell Granulated |

| VOC Filtration: | Optimal |

| Particulate Matter Filtration: | Yes |

| Ethernet: | Yes |

| Wireless Network: | Wi-Fi |

| Network Kill Switch: | Wi-Fi & Ethernet |

| Removable Network Module: | Yes |

| Build Plate Surface (Included): | Bambu Smooth PEI Plate |

| 802.1X Network Access Control: | Yes |

| Hot End: | All-Metal |

| Nozzle: | Hardened Steel |

| Max Build Plate Temperature: | 110℃@220V, 120℃@110V |

| Max Speed of Toolhead: | 500 mm/s |

| Dimensions: | 389*389*457 mm³ |