Sinterit PA11 CF (Carbon Fiber)

$1,050.00

(6KG)

PA 11 Carbon Fiber is a composite material produced from bio-derived castor oil powder, primarily consisting of Polyamide 11, and enriched with Carbon Fiber to improve its performance and rigidity. This material boasts an impressive combination of attributes, including a superior strength-to-weight ratio and excellent thermal characteristics.

With its harmonious blend of mechanical and thermal properties and the added benefit of maintaining robust impact strength, it stands out as one of the most formidable and adaptable options within the SLS powder market.

Product Details

Specifications

Key Characteristics:

- Highest tensile and flexural strength

- Exceptional thermal resistance

- Reliable impact resistance

- Remarkable stiffness

- Satisfactory elongation at the point of break

- Excellent surface quality

- Strong chemical resistance

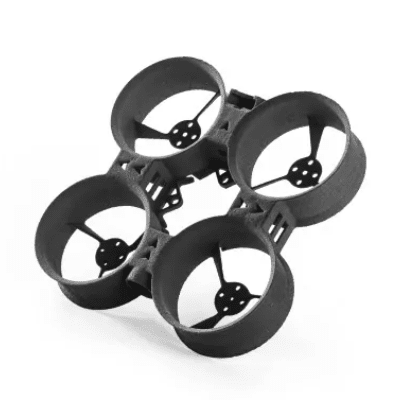

Applications:

- Automotive (for high-performance and metal replacement parts)

- Educational institutions and laboratories (specifically for mechanical and composite purposes)

- Extreme environments (such as motorsports, lightweight structures, and high-temperature applications)

- Maintenance and repair projects

- Medical field (including prosthesis development)

- Aerospace model manufacturing

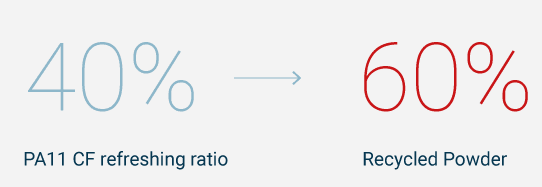

What is the Refresh Rate?

It is the ratio of a minimum amount of fresh powder needed in a mixture of material used in an SLS 3D printer. A lower refresh ratio means better cost-efficiency of the material.

How it Works:

The amount of needed fresh powder is automatically calculated by our software and shown on the printer screen after the print job is finished. Just add shown amount of material into the mixing cycle of used material and you can start your next job with refreshed material

To start SLS 3D printing you need the powder starter pack. After that, you’ll only need to refresh the powder you own with fresh powder.

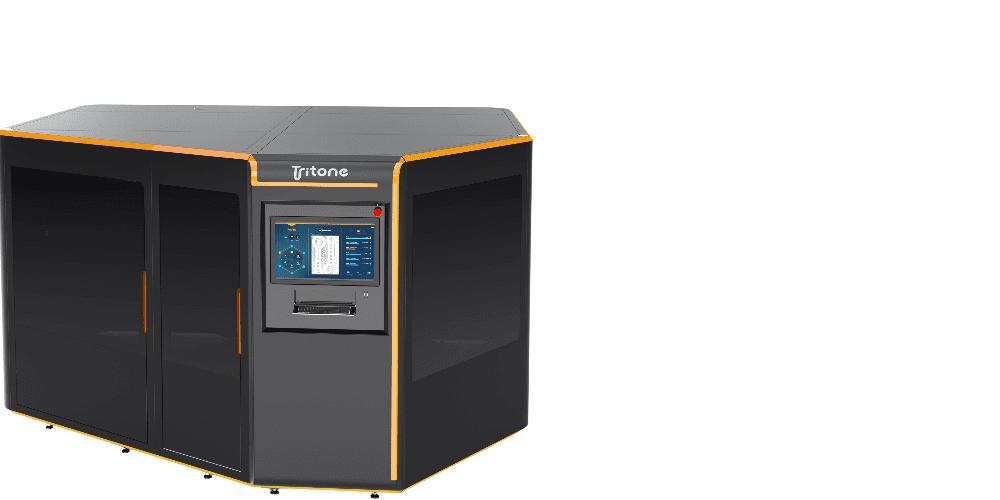

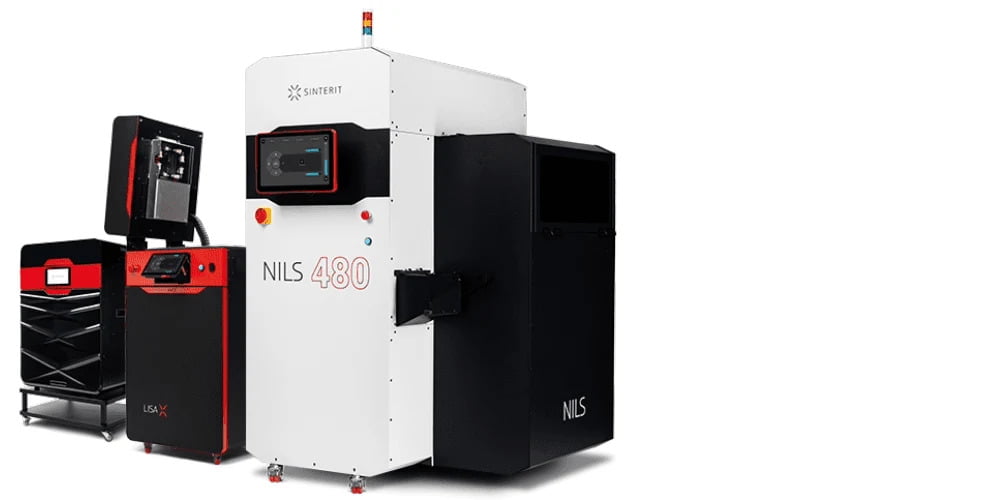

Sinterit PA11 Carbon Fiber

- Dedicated for:Lisa PRO, Lisa X, NILS 480

- Software:Sinterit Studio Advanced

- Nitrogen needed:Yes

- Colour:black

- Refresh ratio:40%

- Bulk density:540 kg/m3

- Printout density:1.09 g/cm3

- Printout water absorption:0.86 %

- Melting temperature:197 °C

- Heat Deflection Temperature A at 1.8 MPa:170 °C

- Heat Deflection Temperature B at 0.45 MPa:191 °C

- Flexural Strength (X direction):100 MPa

- Flexural Modulus (X direction):3050 MPa

- Flexural Strength (Z direction):66.1 MPa

- Flexural Modulus (Z direction):1420 MPa

- Tensile Strength (X direction):81 MPa

- Tensile Modulus (X direction):2950 MPa

- Elongation at Break (X direction):24.5 %

- Tensile Strength (Z direction):47.3 MPa

- Elongation at Break (Z direction):17.9 %

- Impact Strength (Charpy - unnotched):113.65 kJ/m2

- Shore Hardeness in scale:D81

- Storage Modulus (X direction) @23 °C2:4575 MPa

- Loss Modulus (X direction) @23 °C2:172 MPa

- Storage Modulus (Z direction) @23 °C2:3418 MPa

- Loss Modulus (Z direction) @23 °C2:105 MPa