Sinterit PA12 Smooth Fresh

$300.00 - $830.00

A cost effective powder with excellent surface resolution. Perfect for detailed objects and general prototypes.

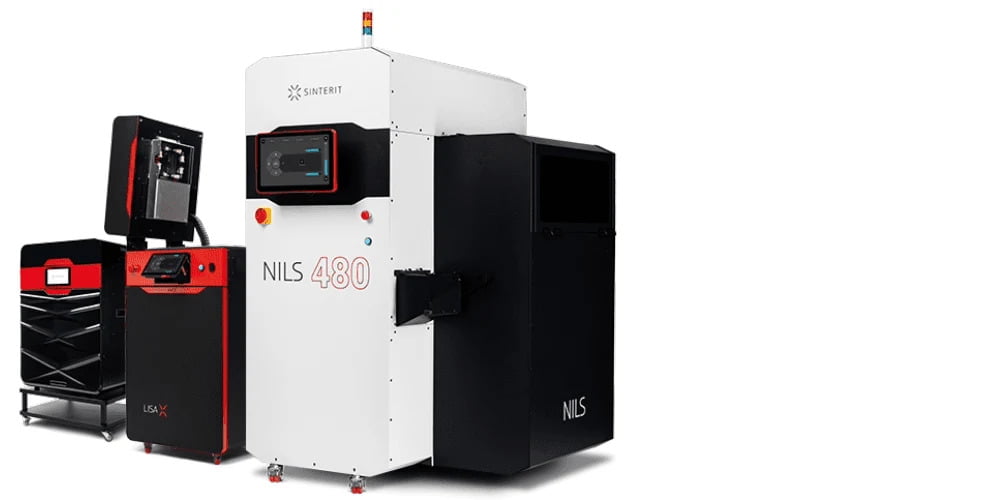

Printer Compatibility:

- LISA X

- LISA PRO

- NILS 480

Product Details

Specifications

Key Features of the Sinterit PA12 Smooth:

- Good quality-to-price ratio

- Excellent quality print surface and details

- High chemical resistance

- Ideal for functional prototyping, detailed printouts, and more

Applications:

- Detailed Printouts

- Complex Spatial Shapes

- Structural or Mechanical Elements

- Functional Prototypes or Final Parts

- Chemically Resistant Objects

What is the refresh rate?

It is the ratio of a minimum amount of fresh powder needed in a mixture of material used in an SLS 3D printer. A lower refresh ratio means better cost-efficiency of the material.

How it works:

The amount of needed fresh powder is automatically calculated by our software and shown on the printer screen after the print job is finished. Just add shown amount of material into the mixing cycle of used material and you can start your next job with refreshed material

How should I store the printing powder?

- Store the powder at room conditions ( ~23°C and 50% humidity – the lower humidity the better)

- Always store the material in a sealed dry box/container.

- Do not leave the container open.

- Clean the machine directly after printing and store the material immediately after removing the print cake.

- Do not let the powder stay in the printer for more than a couple hours.

- Put a few silicone absorbers in the container (but don’t add them to the printer)

Download Technical Data Sheet

Download Safety Data Sheet

Sinterit PA12 Smooth Fresh

- Technology:Powder for Selective Laser Sintering (SLS) 3D Printing

- Material Type:Nylon 12

- Software:Sinterit Studio Basic

- Material refreshing ratio:22%

- Color:Navy Grey

- Nitrogen Needed:No

- Tensile Strength:32 MPa

- Tensile Modulus (Young):1470 MPa

- Flexural Strength:47 MPa

- Impact Strength Charpy Method (unnotched):16 kJ/m2

- Melting Point:185°C

- Heat Deflection Temperature (HDT A/B):68°C / –